Witamy na naszej stronie

Jesteśmy firmą działającą już od 1976 roku. Wszystkie nasze działania oparte są o nasze uzyskane patenty.

Główne nasze prace to ochrona środowiska. Są to opracowania autorskie, wdrożone do produkcji, za które otrzymaliśmy wiele nagród i wyróżnień.

czytaj więcej

Double pistons internal combustion engine

Description

The new conception of combustion engine is based on the combination of two engines. It makes use of both two- and four-stroke engine. The two-stroke combustion engine is characterised by a simple construction and system of air load change as well as bigger index of power output. Unfortunately, its filling ratio is worse than in four-stroke engine. The ecological index of two-stroke engine is also unfavourable. The system of valves of the four-stroke engine is its disadvantage. The cylinders of both modules of double pistons engine have been joined along one axis with common cylinder head - in the form of the ring. The pistons are moved with different speed and with appropriate stage displacement. There are two crankshafts, which are connected with special transmission in shown solution. The four-stroke crankshaft is rotated with twice a speed of two-stroke crankshaft. The engine is named double pistons because of its construction - double pistons and crankshafts.

The double pistons combustion engine's work is based on the co-operation of both modules. The air load change takes place in two-stroke engine. The piston of four-stroke engine is exchange aiding system which improves air load change. It works as a system of valves. The cylinder is filled with air or with air-fuel mixture. Filling proces takes place at overpressure by the slide inlet system. The exhaust gases are removed as in the classical two-stroke engine (by exhaust's windows in cylinder). The fuel is supplied into the cylinder by fuel injection system. The ignition is realised by two spark plugs. The effective power output of the double pistons engine is transfered by two crankshafts. The characteristic feature of this engine is an opportunity of continuous change of cubic capacity and compression rate during engine work by changing the piston's location. The mathematical models (mechanical and termodynamical) were meant for double pistons engines which make ableenable to draw up new theoretical thermodynamic cycle for internal combustion double pistons engine.

Patents:

- Mężyk P.: Combustion engine. Patent nr 195052 dated on 05.10.1999. RP Patent Office, Warsaw 1999.

- Mężyk P, Ciesiołkiewicz A.: Double pistons internal combustion engine. Patent application P-350472 dated on 06.11.2001. RP Patent Office, Warsaw 2001

- Mężyk P, Ciesiołkiewicz A.: Double pistons engine. Patent application P-355931 dated on 11.09.2002. RP Patent Office, Warsaw 2002

Najważniejsze wyróżnienia:

- Złoty medal na 51 Światowym Salonie Wynalazczości, Badań Naukowych i Nowych Technik BRUSSELS EUREKA, 17.11.2002, Bruksela 2002.

- Dyplom uznania Ministra Nauki - Przewodniczącego Komitetu Badań Naukowych prof. Michała Kleibera podczas X Giełdy polskich wynalazków nagrodzonych na światowych wystawach w 2002 r., 17.03.2003, Warszawa 2003.

- Wyróżnienie na EXPO'2003. Stuttgart, Germany, 3 - 5 June 2003.

- Srebrny medal na 103 Międzynarodowym Salonie Wynalazczości "CONCURS - LEPINE" 2004. Paryż, 29.04-09.05.2004.

- Lider Innowacji 2003 Katowice za "Silnik spalinowy M4+2"

- Medal na INTRAG Katowice 2002 dla IZOLING za "Silnik M4+2"

More about double pistons internal combustion engine M4+2®?Send as a question

Introduction

The new conception of internal combustion engine has been proposed by Piotr Mezyk [1] and by Adam Ciesiolkiewicz, Ph.D. evolutes [2,3]. The principle rule of new engine work is based on the combination of two engines: four- and two- stroke in one.

Description

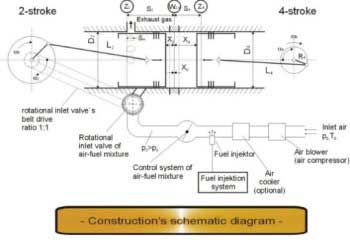

The new conception of combustion engine is based on the combination of two engines. It makes use of both two- and four-stroke engine. The cylinders of both modules of double pistons engine have been joined along one axis with common cylinder head - in the form of the ring. The pistons are moved with different speed and with appropriate stage displacement. There are two crankshafts, which are connected with special transmission in shown solution. The four-stroke crankshaft is rotated with twice a speed of two-stroke crankshaft. The engine is named double pistons because of its construction - double pistons and crankshafts.

Fig. 1.click to zoom

The double pistons combustion engine's work is based on the co-operation of both modules. The air load change takes place in two-stroke part. The piston of four-stroke part is exchange aiding system which improves air load change. It works as a system of valves. The cylinder is filled with air or with air-fuel mixture. Filling process takes place at overpressure by the slide inlet system. The exhaust gases are removed as in the classical two- stroke engine (by exhaust's ports in cylinder). The fuel is supplied into the cylinder by fuel injection system. The ignition is realised by two spark plugs. The effective power output of the double pistons engine is transferred by two crankshafts. The characteristic feature of this engine is an opportunity of continuous change of cubic capacity and compression rate during engine's work by changing the piston's location. The mathematical models (mechanical and thermodynamical) were meant for double pistons engines which make able enable to draw up new theoretical thermodynamic cycle for internal combustion double pistons engine.

Double pistons IC engine features

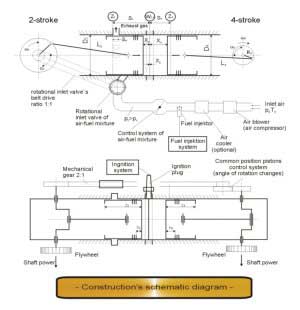

Fig. 2.click to zoom

- The presented IC engine is a double - pistons engine, where the cooperation of two coaxial pistons is used. One piston works in a four - stroke cycle and the second one in the two - stroke cycle.

- The engine's work is based on the modified operation of the two - stroke engine that is cooperating of four - stroke engine piston. Exhaust gases are thrown out through exhaust's ports. The rotary valve controls the supply of the fresh air - fuel mixture.

- The modified operation of engine's work is realized as a result of:

- the quotient of pistons strokes (k=S4/S2 in (1/2, 1)),

- the possibility of changing relative piston's position during the engine's work via automatic change of crankshaft's polar position (alfa=40stC[+-]20stC).

- When the volume of workspace decreases the charge exchange is beginning. There is a clear separation of scavenging phase and relative filling phase. The fresh air filling appears with overpressure. Than the volume of cylinder's workspace is almost constant. The engine's work at the whole working field requires using a mechanic compressor.

- Advantages of the modified charge exchanges are:

- an increase of cylinder filling's coefficient,

- an appropriate cylinder's scavenging

- the possibility of influencing the charge's exchange via steering initial inlet of the fresh mixture.

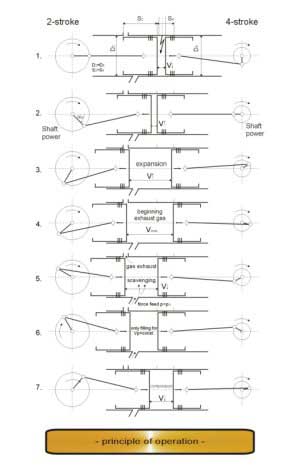

Fig. 3.click to zoom

- The engine is characterized by:

- lingered gas's expansion and limitation of the exhaust gas's temperature on the outlet,

- the variability of the compression ratio (from the low order of 6...7 to the high order of over 12),

- possibility of changing the compression ratio during the engine's work depending on the temporary load,

- a beneficial changing of workspace during the mixture's compression with different polar position of crankshaft,

- an almost constant increase of volume during the expansion stage at different piston's position,

- the displacement volume is constant - independent of polar angles of the crankshaft changing.

- The property of engine gives possibility to burn different fuels (e.g. bio - fuels and low - octane petrol).

- Based on calculation the new engine has more favorable parameters and work's indicators:

- the increase of engine thermal efficiency,

- a little higher total efficiency (efficiency characteristic is more favorable with medium load),

- a higher torque and the higher power output (compared to the SI engine).

The description of engine

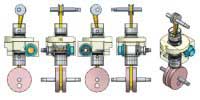

Fig. 1.click to zoom

There is cooperation of two pistons in common working space in new combustion engine. They are backward coaxial running in two modes: two- and four-stroke for one work cycle (engine name). The cylinders of both engine modules (two- and four-stroke) have been joined with common head - ring. The pistons are moved with different frequencies with appropriate stage displacement. There are two crankshafts in the presented solution. They are synchronized by connecting these crankshafts gear rotations - the four-stroke crankshaft is rotated with twice a speed of two-stroke crankshaft. The ideological scheme of construction of double pistons engine is presented in the Fig.1.

The description of engine

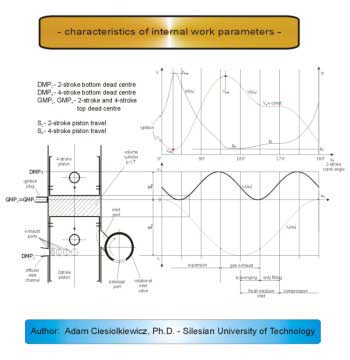

Fig. 2.click to zoom

The air load change system takes place in two-stroke module. There is the distinct separation of particular phases. First there is the exhaust gas outlet, then the scavenging of cylinder and finally the filling of cylinder with fresh air. The exhaust gas outlet takes place through exhaust ports. These ports have small dimension and are located in the largr partof perimeter of bottom part of two-stroke cylinder. The fresh charge filling (air or air-fuel mixture) is controlled by a rotational valve. The scavenging port is opened with appropriate displacement to exhaust ports opening. Therefore there is the distinct separation of scavenging (the simultaneous opening of exhaust and filling ports) and proper working space filling (there is only filling port open). The schematic work stages location with the characteristic of cylinder's working space volume changes is presented in Fig.2 and the work's stages in Fig.3.

Filling process of working space takes place at overpressure. That is why in an inlet system, the mechanic compressor and the throttle for the regulation of the filling medium is installed. Using the compressor makes additional regulation of combustion engine power possible. This is possible due to medium's overpressure change and the regulation of quantity of air supplied to cylinder. For this reason, in double pistons' engine, the lean mixture combustion is possible.

Fig. 3.click to zoom

The description of engine

The load change is assisted by a four-stroke piston. This piston works as a dynamic boosting system. There is the possibility of influencing the charge exchange via steering initial inlet of the fresh mixture. The changed method of charge exchange brings about the cylinder's filling ratio increasing and the good scavenging of working space. Good scavenging of double pistons engine make possible the same as classic four-stroke engine exhaust gas composition level.

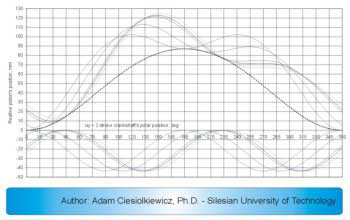

There is a possibility of changing relative piston's position during the engine work. Owing to that there is a possibility of continuous, optimal compression ratio choice for loading. The pistons' stage displacement for the volumes change characteristic is presented in Fig.4.

Fig. 4.click to zoom

The description of engine

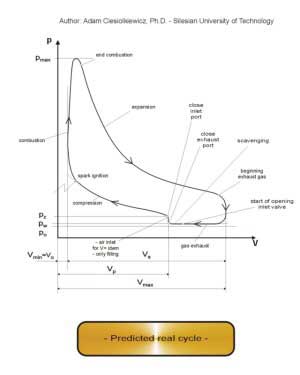

The fuel is supplied by a fuel injection system (to the inlet manifold or directly to the cylinder). The ignition is realized by two spark plugs. The character of fuel-air mixture combustion is mixed (there are two stages: the isochoric and isobaric process). The decompression of gases is prolonged and takes place in full cylinder stroke's volume range. The scheme of thermodynamic cycle (indication diagram) of double pistons engine with the characteristic work points is presented in Fig.5.

Fig. 5.click to zoom

The description of engine

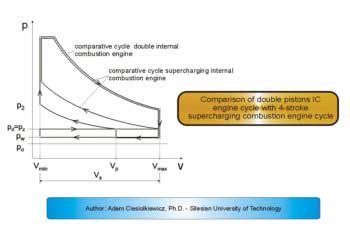

Fig. 6.click to zoom

The theoretic cycle and its compare to charged engine's cycle is showed in Fig. 6. The parameters characteristic of double pistons engine is schematic presented in Fig.7.

Both parts of combustion engines have their own pressure oil systems. Characteristic feature is the extended cooling system of working space. This comes from the heat loads of double pistons engine which is bigger than in four-stroke engine. Two alternators receive the power from both engine parts. One of them is used to start an engine.

Fig. 7.click to zoom

Double pistons IC properties and features

The presented IC engine is a double pistons engine (double crankshafts), where the cooperation of two coaxial pistons is used. One piston works in a four-stroke cycle and the second one in two-stroke cycle.

The crankshafts of both engine parts are synchronically connected with a mechanical gear. There is a possibility of automatic change of crankshafts' polar location.

The engine work is based on the modified operation of the two-stroke engine that is cooperating with four-stroke engine piston. Exhaust gases are thrown out through exhaust ports. The rotary valve controls the supply of the fresh air - fuel mixture.

The modified engine work method comes from the characteristic of two pistons moving. It is realized by appropriate diversified pistons' strokes and their stage displacement.

When the volume of working space decreases the charge exchange proceeds (this process is called "hidden" process of charge exchange on compression stage). There is a clear separation of scavenging phase and filling phase. The fresh air filling appears with overpressure. Than the volume of cylinder working space is almost constant or a little increased (effect of "moving" of volume).

Fig. 7.click to zoom

The engine is characterized by:

- extended gas expansion and limited exhaust gas temperature on the outlet,

- the variability of the compression ratio and possibility of changing the compression ratio during the engine work depending on the temporary load,

- a beneficial changing of working space during the mixture compression with different crankshafts' polar location. That makes the pressure forming in cylinder possible (within reasonable limits)

- an almost constant characteristic of volume increasing during the expansion stage at different piston positions (it influences the steady power transport).

Calculations prove that, the new engine has more favorable parameters and work indicators:

- the increase of engine thermal efficiency (the mechanical efficiency is a little decreasing),

- higher total efficiency - efficiency characteristic is more favorable at medium load. It is comparable with the diesel engine efficiency so the exploitation of fuel consumption is relatively smaller,

- the higher torque and the higher power output compared to the four-stroke SI engine with the same stroke volume.

Preliminary research shows that, the combustion engine has possibility of lean mixtures combustion (lambda>1). The properties and the possibility of compression ratio change during normal work forecast the possibility of different fuels combustion (like vegetable oils, low-octane petrol, bio - fuels with high stage of vegetable components) The properties and features of new engine show that it can work as SI or diesel engine.

The supplementary information

The work with the new combustion engine has been done by IZOLING P.W. Company in cooperation with Silesian University of Technology in Gliwice. There are consultations with researchers from Technical University of Krakow, too. So far two working engine models have been made. The preliminary model is based on two existing engines (two-stroke motorbike engine and four-stroke small machine engine). This model confirms the rightness of two- and four-stroke engines connection. The second model is the functional model. It realizes the elaborated engine work conception. The new solution of combustion engine was presented during Scientific Conferences (KONES '2002, Seminary of bio - fuels 2003, etc.) and in mass media (journals, newspapers, TVP, radio).

The hope to build modern and universal ecological engine with good technical parameters and low fuel consumption is connected with Double pistons internal combustion engine.

SELECTED EXPLANATIONS ON THE OPERATION, PROPERTIES AND APPLICABILITY OF THE TWO-PISTON COMBUSTION ENGINE.

We are presenting the answers involving the problems that you were interested with respect to the operation, properties and applicability of the two-piston engine.

Work discontinuity of the piston and piston rings assembly with the sleeve surface of the two-stroke part of the engine.

The two-piston engine is an engine in which the working surface is made up by a cylinder and two pistons running in it backward-wise with different frequencies. In one cylinder there is a two-stroke part and four-stroke part. The two-stroke part is made up by a typical sleeve with respective ports: inlet port and exhaust port, and the four-stroke part is a sleeve with smooth internal surface. The sleeves of both parts are connected with each other by a common ring. As it happens in such cases, the ports in the cylinder of the two-stroke engine bring about discontinuity of work in the area between piston rings and sleeve gliding surface. However, the two-piston engine has innovative timing gear ports, as for the two-stroke engine,. The exhaust ports are made up by a row of many small-diameter wheels situated around a considerable part of the circumference at the very end of the piston stroke of the two-stroke engine. And the inlet port is situated above the exhaust ports (The distance between the raw of exhaust ports and the inlet port is several millimeters) and covers the range of piston travel at which the exhaust gases in the working area are decompressed to low pressure (about 5% of the maximum pressure) and their temperature is below 1000K (about 40% of the maximum temperature). The shift of timing gear ports in a two-stroke engine is different in our project as compared to a typical two-stroke engine, where the said ports are located within the same range of piston positions. The inlet port has a specific geometry which has not been so far exposed in our elaborations – it is one of the fragments which has been covered by patent application. The said solutions minimize the discontinuities and in our opinion contribute to further development of timing gear in a two-stroke engine.

Efficiency of cylinder scavenging.

The process of charge exchange in a two-stroke engine is a process in which particular phases are distinctly separated: first the outlet of exhaust gases is taking place with a considerably high pressure difference of the agent, then we have the scavenging phase of working area of the cylinder with the overpressure of fresh charge, and finally the last phase where filling is taking place, also with overpressure. The accepted concept is different from that in a typical two-stroke engine, it is similR to the exchange in a supercharged four-stroke engine. In our case, the factor which is relevant and which influences the scavenging and filling is the possibility to change the characteristic of working volume of the cylinder during these phases of engine work. During the outlet of exhaust gases and scavenging the volume is decreased, and during the phase of actual filling the volume of working area is almost unchanged, which results from an interesting kinematics of the system with two crankshafts. Due to the above the opening time of the timing gear ports during scavenging and filling is appropriate. Furthermore, the regulation of pressure of the charging agent (mixture or air) is also influencing the quality of charge exchange.

The elaborated method of working agent exchange enforced a respective position of timing gear ports on the surface of cylinder sleeve (point 1) and the application of inlet valve. By a respective control of this valve we can correct the scavenging phase – accelerating or slowing down its beginning. A good efficiency of scavenging and filling processes is also influenced by the geometry and position of the channel joining the rotation valve with the inlet port in the cylinder as well as by the geometry of the inlet port itself (point 1). In both cases we ensured respective angles at which the channel and inlet holes are positioned in the cylinder sleeve. Furthermore, during the exchange of the charge a very important support of the piston in the four-stroke part is taking place – it is a dynamic reaction.

The presented solutions are more advantageous than the ones in typical two-stroke engines, and they seem to be effective. In view of the investigation studies carried out to date, there is no indication that the scavenging and filling processes are less effective, but more detailed conclusions can be arrived at after further and more detailed investigation studies.

Recently, the scavenging phase of the cylinder has been modified to a relatively high extent – a respective constructional system is somehow complicating the timing gear of two-piston engine, but on the other hand it results in radically better efficiency of agent exchange. The discussed solution is presently in the designing stage.

Costs of the systems with two crankshafts.

The engine with two crankshafts results in the situation where the engine has to be developed by adding another crankshaft assembly, which will definitely result in higher construction costs of new engines. We must remember, however, that in the two-stroke engine the timing gear system is relatively simple, which will in turn reduce the overall costs. All in all, the production cost of the new engine is comparable to the price of new four-stroke engines with a developed timing gear system. We should also emphasize that in the discussed two-stroke engine we can regulate relevant geometric features using relatively simple methods.

Problem of synchronized system with two crankshafts

By the application of a synchronized drive with two crankshafts, with possible automatic control of piston positions with respect to each other, the two-piston engine has two very important characteristics: changeable compression level during the compression of the agent, effect of prolonged expansion of working agent.

The changeability of compression level is a very desirable feature in modern engines, since for different loading conditions resulting from particular exploitation conditions of the engine, the engine with spark ignition should work with the optimal value of compression level. With respect to the medium and steady loading (partial dosing of fuel) high compression level is most advantageous (whereby the consumption of fuel is considerably reduced), whereas with higher loading of the engine the said level should be reduced – when higher power of the engine is required and combustion knock is to be avoided. At the same time, the changeable compression level makes it possible to apply different sorts of fuel, which eliminates knocking. And the effect of prolonged expansion (decompression) has a considerable influence on the increase of internal (thermal) efficiency of the engine. A certain decrease of mechanical efficiency due to the application of two crankshaft assemblies is compensated by the effect resulting from a considerable increase of internal efficiency, which in consequence brings about a considerable increase of overall efficiency of the engine. And finally the consumption of fuel in the two-piston engine will be each time lower.

The characteristics of the two-piston engine obtained through mechanical tests resulted in the elaboration of thermodynamic cycle. It is a modified cycle combining the advantages of Atkinson’s cycle (cycle with prolonged decompression) and Miller’s cycle (cycle with a possible change of compression during the compression stage) and it eliminates the disadvantages of these cycles (complete decompression to the initial pressure in the case of Atkinson’s cycle and worse filling in the case of Miller’s cycle). In our case the decompression is taking place to low values of pressure and temperature of the agent, with proper filling of the working area of the cylinders.

Detailed values of the obtained effects can be determined through investigation studies. We presume that the application of the system with two crankshafts and of the system synchronizing the position of the crankshafts will not bring about lower life of the engine. However, there is a problem involving the passage and further transfer of power from both parts of the engine. We are planning to apply two electric power generators (separate for each part of the engine) and the proposed driving system is a hybrid one (combustion engine + generators + electric engines). The drive synchronizing system does not increase noise level, which has been confirmed by the investigation studies on the two-piston engine. Also the vibration level of our engine is relatively low.

Problem of complete combustion of fuel

The process of fuel combustion in two-piston engine is more advantageous than that in a typical two-stroke engine, but there are some gaps (e.g. the area joining the inlet port with the rotational valve) and it can bring about incomplete combustion of the fuel. Therefore, the best fuel feed system in the two-piston engine is the system with direct injection (GDI). Other characteristics (e.g. ring volumes) are similar to those applied in typical piston engines and have no considerable effects on the lowering of combustion level of fuel.

Engine performance with weak mixtures being applied

With two-piston engines, weak mixtures can be applied. In the case of the engine AI working with l>1 there are some difficulties with exhaust gas purification, yet there are some solutions reducing the emission of all basic toxic substances (carbon oxide, hydrocarbons, nitric oxide). In such a situation, the exhaust system should be furnished with the double catalytic system of exhaust gas purification – near the engine just after the exhaust collector, a three-function catalyst is to be installed as a pre-catalyst, and farther from the engine a NOx trap is to be installed as the main catalyst. During the performance of the engine fed with weak mixture, the three-function catalyst oxidizes properly carbon oxide and hydrocarbons due to the increased share of oxide in the exhaust gases, but it does not eliminate nitric oxides (NOx) present in exhaust gases. Therefore, an additional catalyst is to be applied – NOx trap catalyst. It is constructed in the same way as the three-function catalyst, but despite the coat platinum-palladium-rhodium , it also contains some specific admixtures which can accumulate nitric oxides. The films accumulating NOx are coated on a common carrier. During the work of the engine with stoichiometric mixture (l=1) the trap catalyst is working as a three-function catalyst supporting the work of the pre-catalyst, and when working with the weak mixture, the catalyst transforms the nitrite oxides which have not been reduced in the three-function catalyst.

The transformation is carried out in a periodic way and has three phases:

- accumulation of NOx,

- discharge of NOx,

- transformation of NOx.

First the oxidation of nitrite oxide (NO) to nitrite dioxide (NO2) is taking place, and then NO2 is reacting with oxygen and specific oxides (e.g. barium oxide BaO) deposited on the catalyst’s surface, forming nitrates. The increased charge of accumulated nitrite oxides reduces the catalyst’s potential to collect them any further. In that way the regeneration of catalyst is taking place (discharging and transformation of NOx) by short-term working of the engine with rich mixture (l£0.8). Then, in effect of higher emission of carbon oxide and hydrocarbons in exhaust gases, NOx is reduced (transformed) into nitrogen and carbon dioxide. The capacity of NOx accumulation in the trap catalyst is strongly dependent on the temperature of gases, with the best results being obtained at the temperature 300..400C. The range presented above is much lower than the level of temperature in the three-function catalyst, in which the best results are obtained with much higher temperature of exhaust gases. Therefore the trap catalyst is installed a bit farther from the engine when the exhaust gases have been cooled down in the exhaust pipe.

The proper functioning of the double catalyst system necessitates the application of two lambda probes – one with the three-function catalyst and the other with the trap catalyst (it is a two-state probe with a NOx sensor built in) and a temperature sensor installed after the three-function catalyst.

A currently observed fast development of catalytic purification methods is following the demand to find most efficient and effective methods to face the problem of exhaust gas purification. The problem entails, however, more complicated systems to be applied as well as higher costs.

With respect to the two-piston engine, which is a new technological solution, there are definitely some problems to consider carefully. The problems are accordingly considered and appropriately approached.

AUTOR: Piotr Mężyk & Adam Ciesiołkiewicz.

Wszelkie prawa zastrzeżone © Izoling-Akam Sp. z o.o. | Wykonanie jusnet.pl